WAGNER

THE RIGHT TECHNOLOGY

FOR INDUSTRIAL PAINTING

ARE YOU INTERESTED?

CONTACT US:

| Phone: | +421 2 4341 5963 |

| +421 2 4363 8407 | |

| E-mail: | office@kzsro.sk |

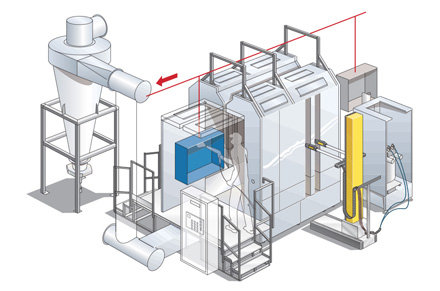

SUPER CUBE - Custom-made plastic booths

THESE BOOTHS ARE DESIGNED BY WAGNER ACCORDING TO THE CUSTOMER'S INDIVIDUAL NEEDS.

THE PROJECT DEPARTMENT WILL QUICKLY PREPARE A QUOTE AS FOLLOWS:

- SUPER CUBE - plastic booth

- Monocyclone

- CORONA – manual spray guns

- CORONA – automatic spray guns

- Powder paint centre

- Manipulators

- Other individual components

BENEFITS:

- This is an innovative, partially automated plastic (PVC) booth technically designed for fast and easy colour changes

- Short booth (only 2.5 m long) – requires only a small amount of powder in the system to achieve constant, high-quality production

- An automated suction system, which extracts excess powder to the powder centre during the application of paint, is installed over the whole length of the booth to attain optimal coating quality

- Manual application (pre- and post-spraying) takes place on a pedestal outside the booth, resulting in excellent manual coating quality

- The booth's suction system is designed to allow optimal vacuum-induced internal flow

- The offer includes a broad range of accessories for powder replacement and maintenance

- The booth is intended for bespoke painting using many colours, with high demands on surface quality

WAGNER offers clients the services of the "TECHNIKUM" laboratory to facilitate optimal equipment selection. The results are reports of tests done on the client's particular products.

Our current projects

Manufacturing and supply of TD thermal cleaning equipment for clients in:

Arens, Czech Republic

Entlackungsfabrik, Germany

Tiefenbacher, Austria

Delivery of Wagner powder coating technology from Germany to a client:

Komad, Slovak Republic